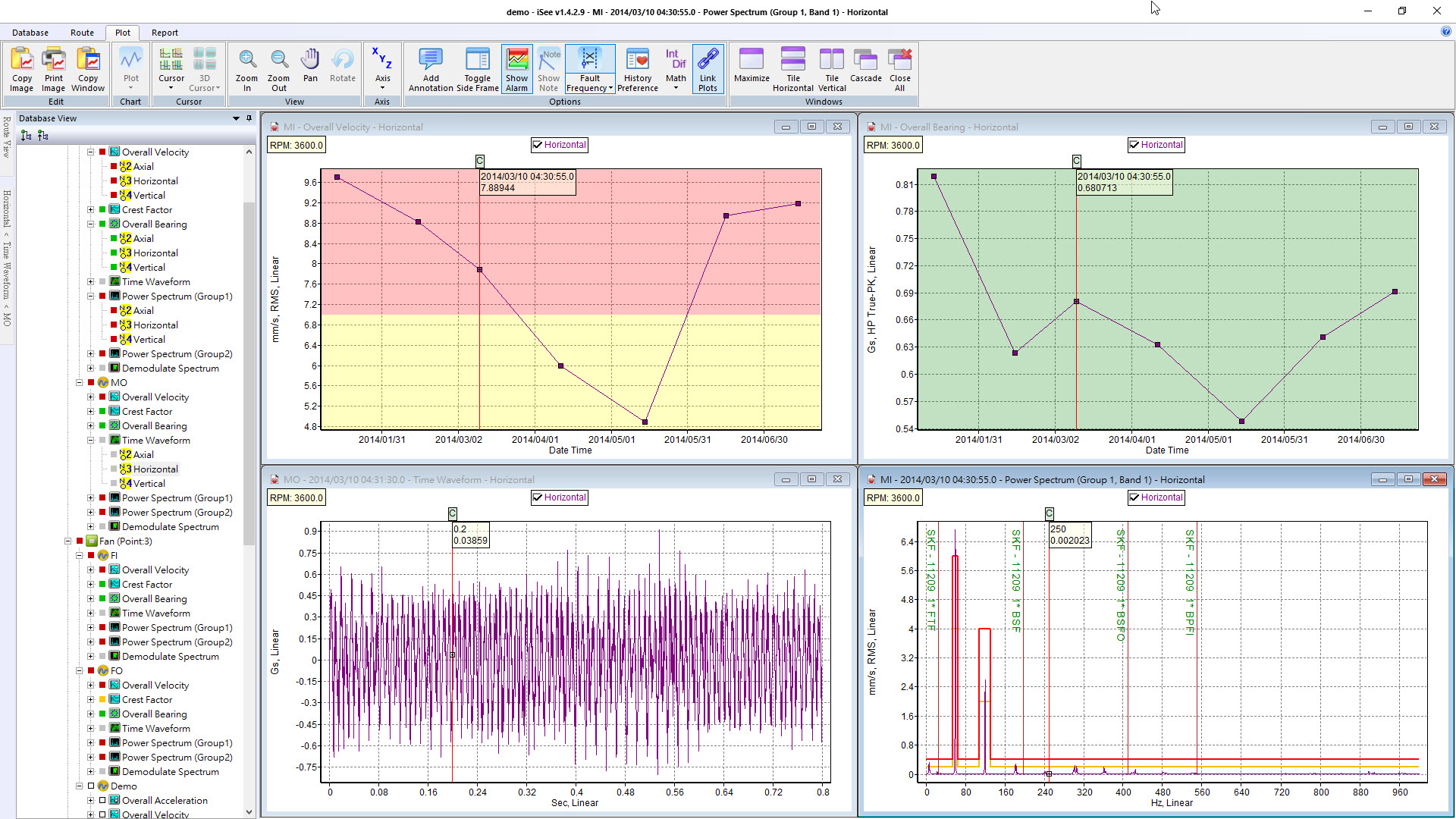

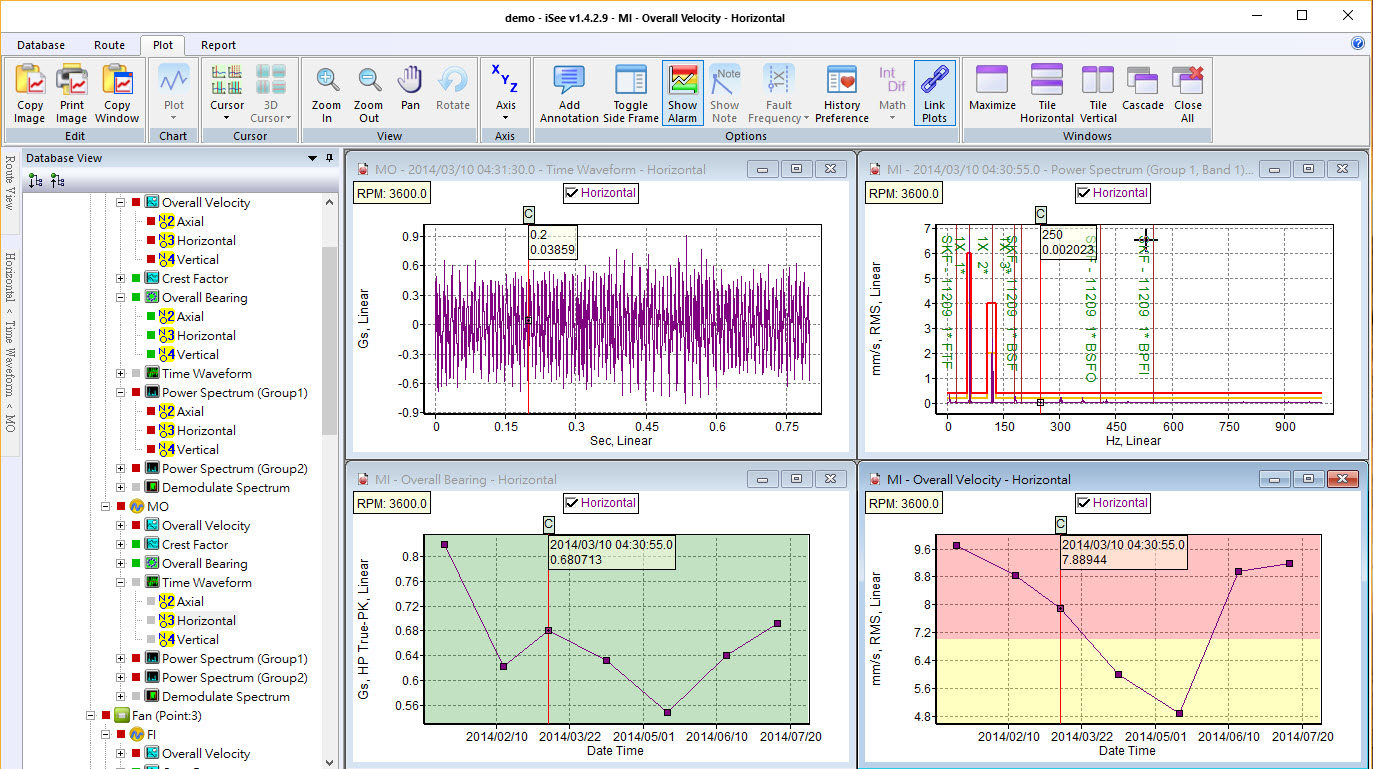

iSee Predictive Maintenance Software

For machinery that requires long and stable working times, unexpected damage and shutdowns are unwanted situations as these could lead to production line shutdown or product damage. In the early stages of a malfunctioning device, if no proper actions are taken, this could lead to serious device damage and other safety issues. The iSee predictive maintenance system is software that is designed to solve this. Through simple regular inspection, iSee can help manage the state of machinery, discover malfunctions in advance, and help arrange proper maintenance plans to lower repairing costs and to keep production lines efficient.

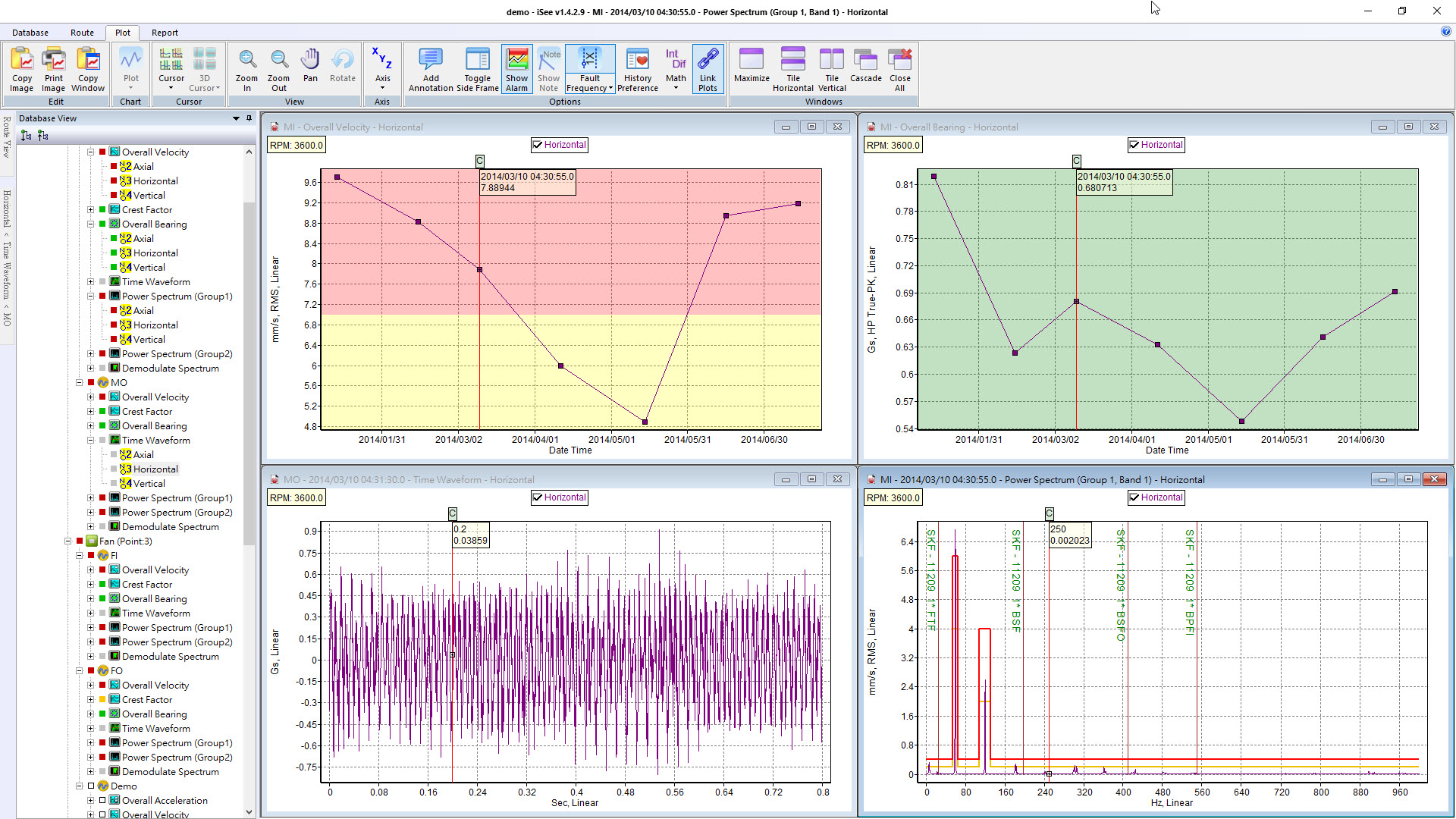

- iSee features easy and intuitive UI, which is easy to navigate for beginners or experienced users.

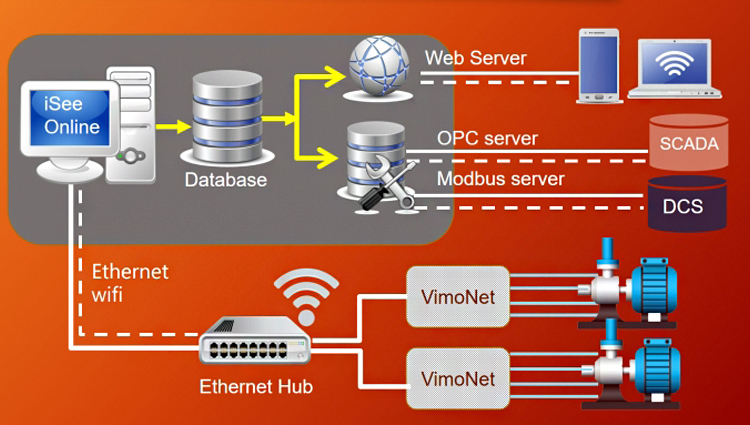

- iSee software uses a portable data collector such as impaq Elite/Fieldaq II or vPod Pro to form a complete predictive maintenance system. It can support all your daily inspection tasks and device health monitoring needs.

- In a few easy steps, the iSee predictive maintenance system can print out all needed reports or any device data that is in a state of alertness for data inspection. You can also go through these re-ports, spectrums and trends and toggle them to print them out at once.

Measuring features:

- A hierarchical structure based on requirements to choose from.

- A total of 6 sensors available

- A total of 12 measurement types

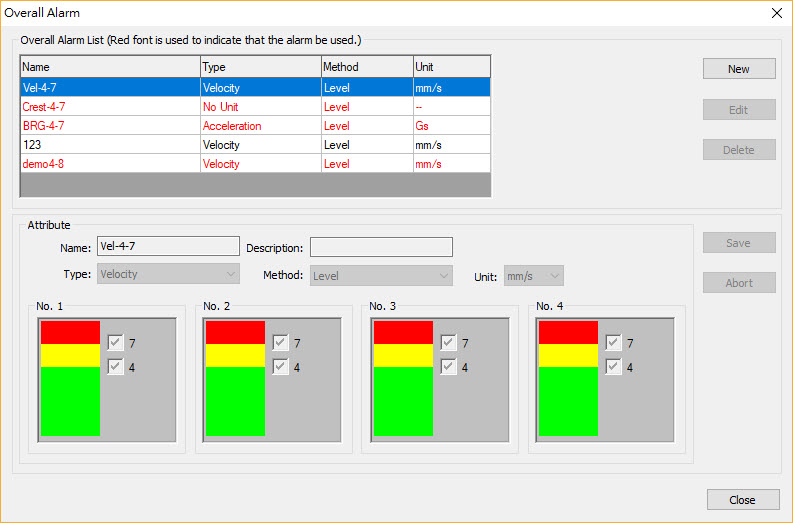

- Level Overall Alarm setting available

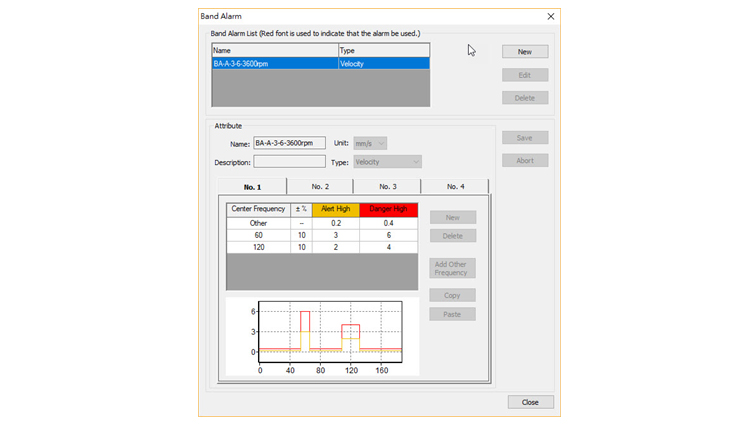

- Band Alarm setting available

- Fault Frequency bearing setting available

- Built-in bearing database

- Vibration inspection

- Vibration monitoring and predictive maintenance