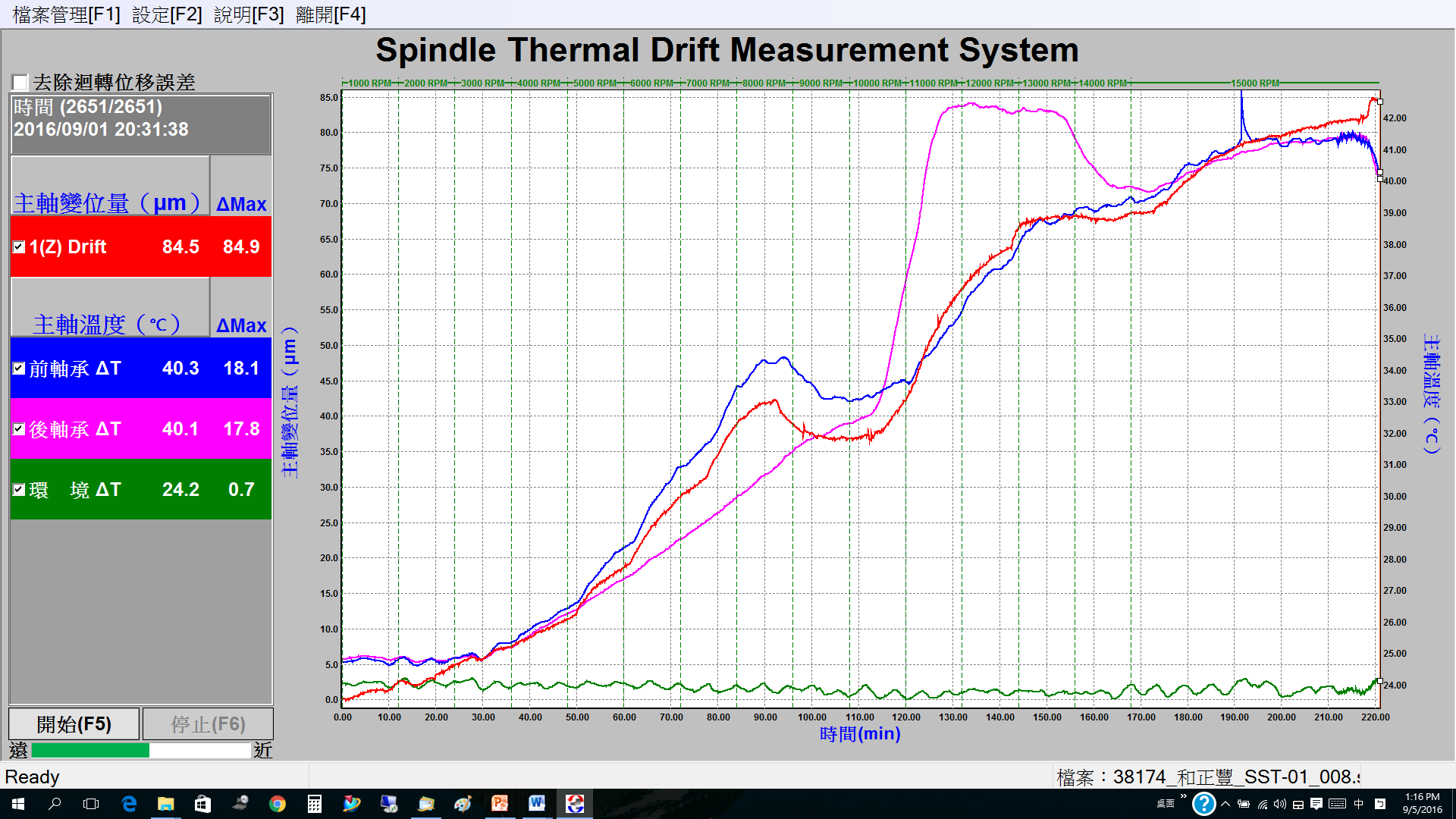

STDM (Spindle Thermal Drift Measuring System) is a measurement device for detecting the ther-mal deformation and deflection of the spindle of a machine tool. It can measure the displacement of the spindle in three axes and the temperature value of each point of the machine.

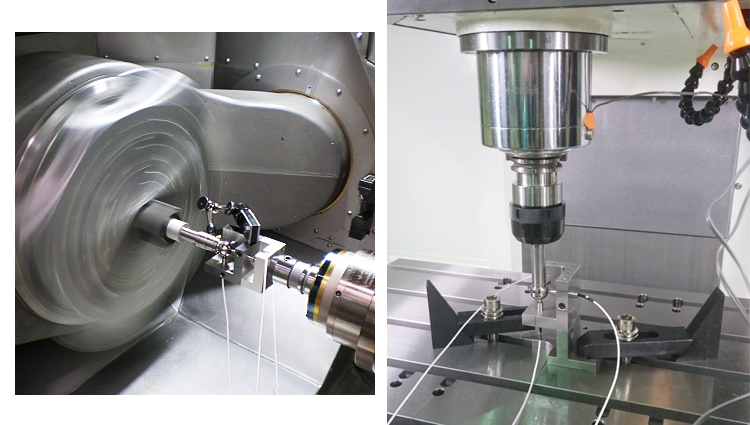

Thermal deformation is the main source of error in machine tools. When the machine tool is started, the structure is deformed or bent due to heat, which will change the position of the tool tip point, thus causing errors in the shape accuracy of the workpiece and the depth of the machined hole.

Uneven heat source causes distortion and deformation of the tool structure. This tilts the spindle tilted and will result in hole deflection and poor surface flatness or surface roughness of the ma-chined part.

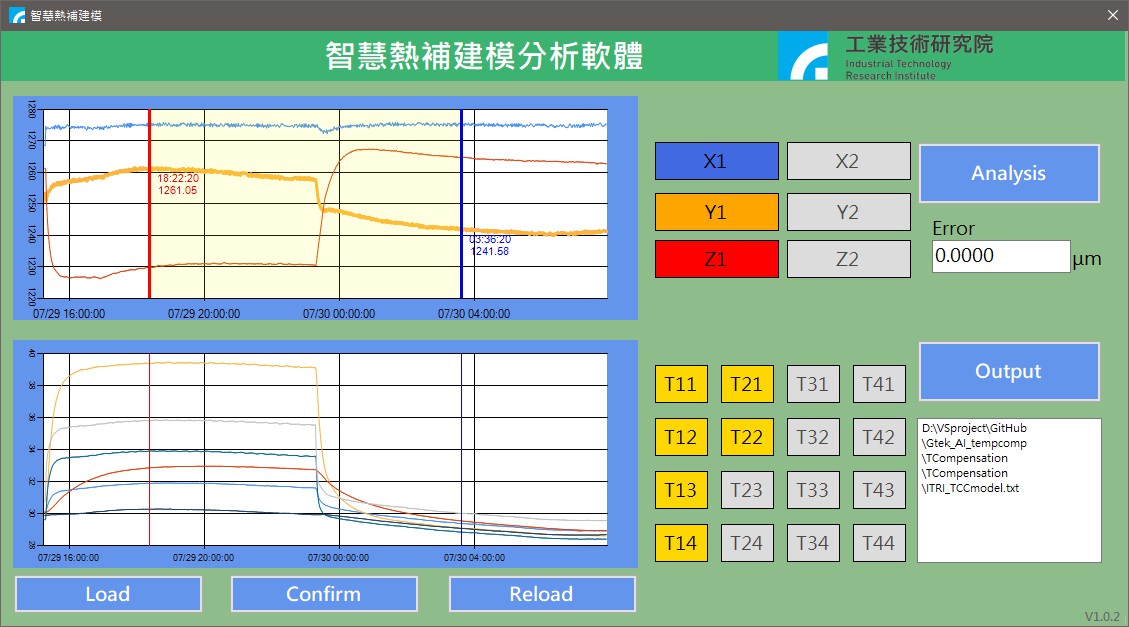

Measuring the thermal deformation of the machine tool allows the user to understand the thermal stability of the machine and the change in displacement caused by temperature increases in precise machining.