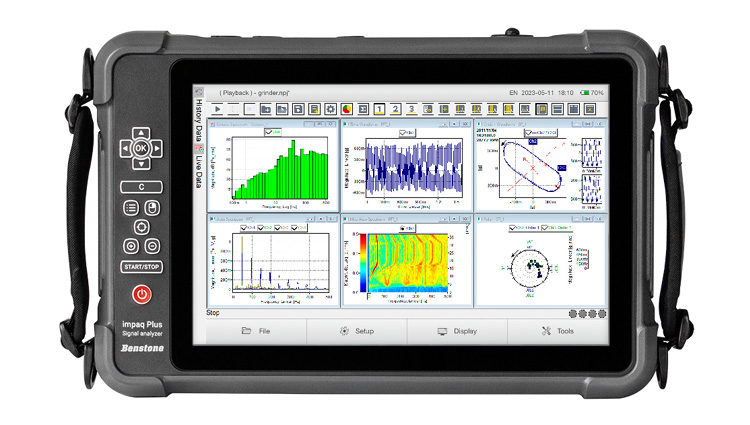

Fieldpaq III 2-channel handheld Vibration has a 7-inch 1280×800 TFT color touchscreen, providing clear and comprehensive information display. It features a new touchscreen human-machine interface combined with physical buttons. The ergonomic soft-grip handle and shoulder bag design facilitate easy carrying and operation.

Compliant with IP65 waterproof and dustproof standards and CE safety certification, it offers excellent drop protection, allowing safe measurements even in harsh environments. It features a built-in high-capacity rechargeable battery for prolonged data collection and analysis.

- Windows IoT operating system, built-in 128GB storage memory. It can also transfer data to a PC using a Accessories G168-USB cable.

- Up to 100 dB dynamic range, the real-time measurement frequency range reaches 40kHz.

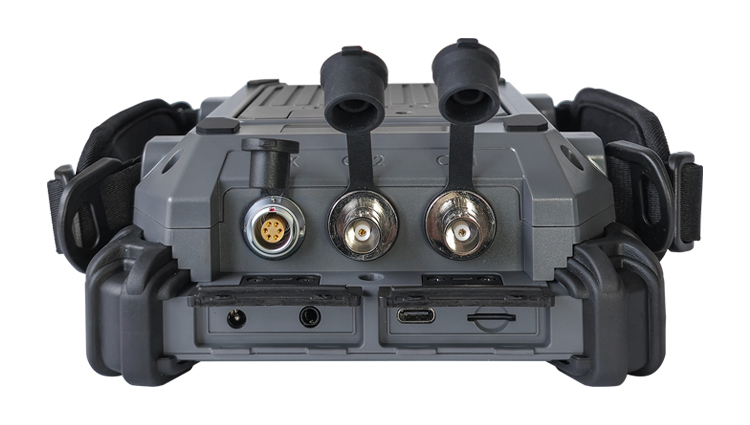

- Provide 2 sets of BNC connectors for analog signal input, compatible with various sensors, and 1 LEMO 6 PIN connector (AUX) for connecting a laser tachometer.

- LEMO 6 PIN AUX connector provides additional expansion with 2 analog signal inputs for use with 3-axis sensors.

Balancer

Balancer module can balance your rotating machines in the field provide single plane, dual plane, 3 plane, 4 plane, overhung dual plane, 3 weights balancing, Additional features:1X coast down order trace, decoupled balancing(static and couple), unequal radii, component calculation, drill depth, vibration history, balancing history and recalculation of balancing coefficients.

Vibration Meter

Measurement of overall vibration from channels 1 to 4, simultaneously displaying displacement, velocity, and acceleration of mechanical vibrations. It allows recording vibration trends over time or speed changes. Built-in standards include ISO 20816-3 and ISO 17243-1/2/3 for rotational machinery vibration measurement, along with customizable filters.

FFT Spectral Analysis

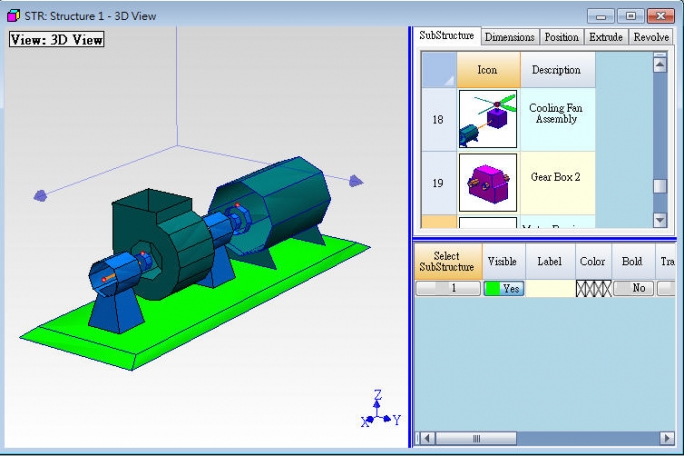

Experimental Modal Analysis Test (EMA), Frequency Response Function (FRF), Operating Deflection Shape (ODS) FRF Test, Power Spectrum Analysis, Envelope Spectrum Analysis, 3D Waterfall Plot, Intensity Plot, Bearing Diagnosis Analysis, & more.

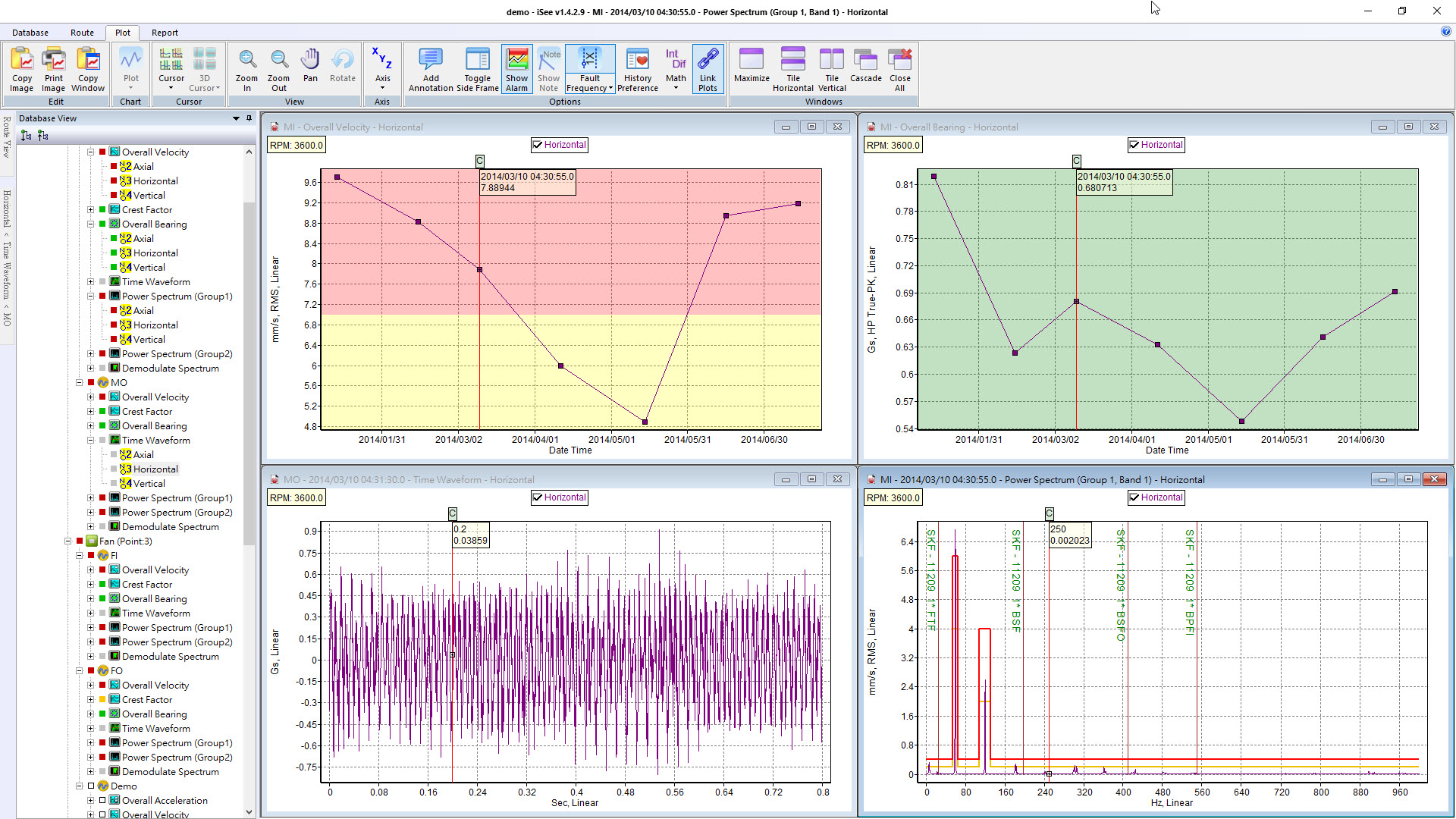

Data Collector

Route Based Data Collector module and recording of customized process parameters during inspections. Using the iSee software on a PC, engineers plan inspection routes and select data collection types. These are uploaded to the data collector function of Fieldpaq III. Engineers then visit the site to record vibration data and process parameters of rotating machinery equipment along the inspection routes. Subsequently, the collected data is downloaded to the iSee software for predictive maintenance and trend analysis management.

Optional software:

1. Balancer

2. Vibration Meter

3. FFT Spectral Analysis

4. Data Collector(Combined with iSee Software)

- Dynamic balance

- Vibration inspection

- Modal and operational vibration measurement

- Vibration measurement

- Noise analysis