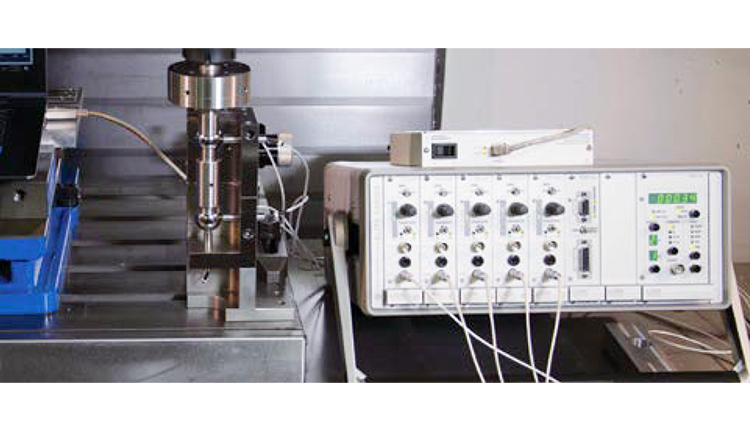

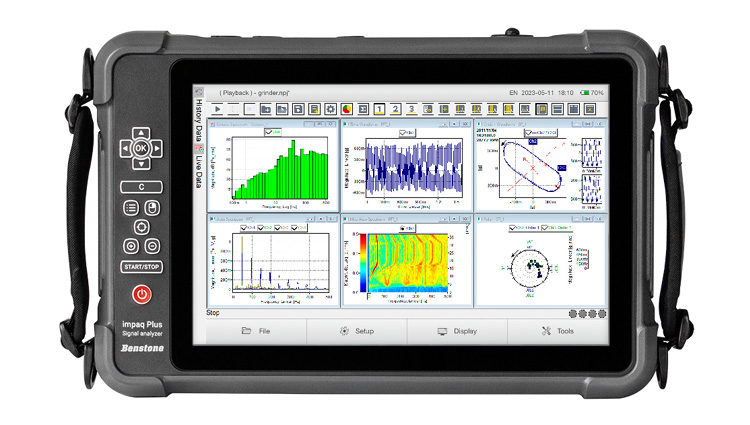

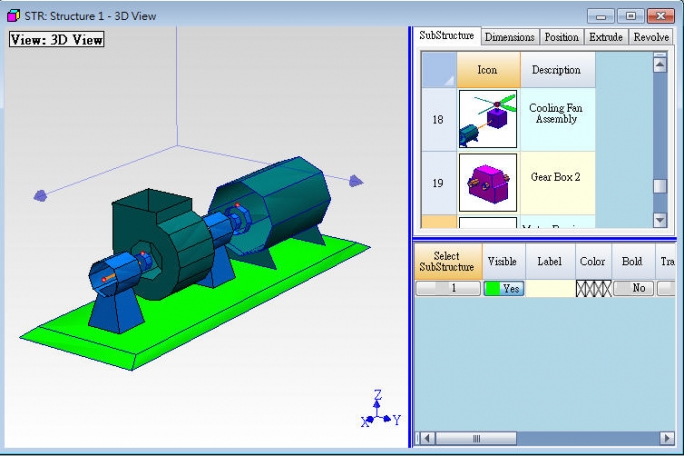

Spindle performance is the key to the quality of machining. When you understand spindle perfor-mance, you can predict and control the quality of the machined part, the shape accuracy, roundness and surface roughness, which are all related to spindle performance. Only by measuring the spindle accuracy at the real processing speed of the spindle, can there be meaningful quality control of the machined parts. Therefore, it is important to measure and understand the performance of the ma-chine tool to determine the best working speed and warm-up time or even confirm the accuracy of the spindle before and after a machine crash.

Spindle performance is the key to the quality of machining. When you understand spindle perfor-mance, you can predict and control the quality of the machined part, the shape accuracy, roundness and surface roughness, which are all related to spindle performance. Only by measuring the spindle accuracy at the real processing speed of the spindle, can there be meaningful quality control of the machined parts. Therefore, it is important to measure and understand the performance of the ma-chine tool to determine the best working speed and warm-up time or even confirm the accuracy of the spindle before and after a machine crash.

Spindle performance is the key to the quality of machining. When you understand spindle perfor-mance, you can predict and control the quality of the machined part, the shape accuracy, roundness and surface roughness, which are all related to spindle performance. Only by measuring the spindle accuracy at the real processing speed of the spindle, can there be meaningful quality control of the machined parts. Therefore, it is important to measure and understand the performance of the ma-chine tool to determine the best working speed and warm-up time or even confirm the accuracy of the spindle before and after a machine crash.

Spindle performance is the key to the quality of machining. When you understand spindle perfor-mance, you can predict and control the quality of the machined part, the shape accuracy, roundness and surface roughness, which are all related to spindle performance. Only by measuring the spindle accuracy at the real processing speed of the spindle, can there be meaningful quality control of the machined parts. Therefore, it is important to measure and understand the performance of the ma-chine tool to determine the best working speed and warm-up time or even confirm the accuracy of the spindle before and after a machine crash.